19th September 2022

Reliable, Convenient Fast Charging Will Drive the Future of EV Adoption

For consumers in developed nations, lifestyle convenience is ingrained. We don’t know what it’s like not to have access to necessities – food, water, clothing, housing and transportation – not to mention luxuries. When it comes to dependency on automotive transportation that, too, is built on confidence around readily-available fuel. In urban areas, there’s a gas station on every corner. The societal transformation that has occurred because of automotive technology is stunning; and, now, the auto sector is set to enter a new era of e-mobility. While electric vehicles (EVs) have been available for decades, next-generation electronic innovation and rechargeable battery technology have moved the needle from EVs as a novelty mode of transport to a reliable combustion engine alternative.

With a healthy nearly 30% compound annual growth rate (CAGR) projected over the next decade, there could be over 30 million EVs on the road globally by the year 2030(1). Consumer sentiment around battery-operated EVs has witnessed a dramatic shift in recent years, and EV sales as a percentage of total car sales have continued to steadily climb. While this is a promising development toward meeting the goals of CO2 emission reduction, a looming roadblock remains: access to charging power.

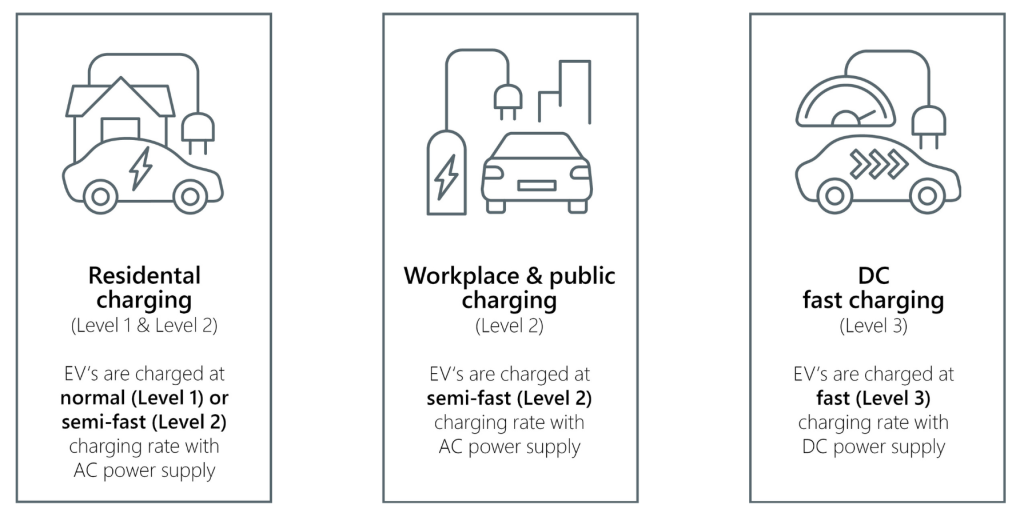

The EV charging infrastructure, while markedly improved with the expansion of EV ownership, is a long way from parity with the availability and speed of a refuel at the pump. Opportunity charging via residential or commercial (workplace and public spaces) connection comprises the vast majority of battery charging events and is the most practical for numerous reasons. An overnight plug-in at home will fully charge most EV batteries and a top-off while at work or the grocery store can help keep enough power for around town movement. But a few hours’ AC charge will not suffice for long distances like vacation travel. For extended journeys, access to robust fast charging stations that can provide a charge in 30 minutes or less is required.

Without an expansive DC fast charging infrastructure to supplement residential and public/workplace access, the projected dramatic rise of EV sales through 2030 may sputter. Numerous factors will influence accelerated development of the global charging network – from public policy to funding initiatives to technology innovation. No matter the charging level device, however, consumers expect reliability and dependability – just like the gas pump. The systems have to work and building them to last will increase trust and encourage more widespread use. Imagine pulling into a charging port to find the connector gun broken or the entire unit out of service; too many experiences like this and the enthusiasm about EV ownership may wane. For our part, Henkel is working to ensure dependability within all types of EV charging devices to shape consumer confidence at the port, just like exists at the pump. Effectively dissipating heat – all the way up to the 400 – 1000 V of fast chargers – is a key piece of the reliability equation, as are protective potting solutions for securing critical wires and coils, and gasketing materials that prevent ingress of environmental contaminants into charging units.

DC fast chargers, which is arguably where expansion is required, system reliability is a must as these units are expected to last as long as 10 years in the field. They are costly to produce and, therefore, performance and durability are critical. Functionality of the device’s workhorse power module – now smaller in size with higher power densities than previous-generation designs – can be optimized by effectively dissipating operational heat; Henkel’s low thermal resistance phase change thermal interface materials are a proven solution and a superior alternative to grease, which can lose effectiveness over time. The importance of sound thermal control cannot be overstated, especially with systems that are managing such high power. Securing the unit’s interior structure to protect its electronics is made possible with UL-certified Sonderhoff Fermapor K31 formed-in-place foam gasketing (FIPFG) system, which allows high automation, fast deposition for complex shapes and changing designs. Units are protected from dust, moisture and other environmental contaminants while delivering fast shape recovery for confident serviceability. And, as drivers will attest, charging connectors take a beating with users plugging and unplugging quickly. High-performance, cost-effective potting materials fully encapsulate the cables and wires within the charging gun connectors to provide rugged durability in changing outdoor environments and manage the stress induced during user plug-ins.

While these are only a few examples of Henkel material solutions in the EV charging infrastructure ecosystem, they are integral to building long-lasting, functionally and electrically sound devices that will foster EV owner trust and drive needed additional investment.

Explore Henkel’s solution portfolio for EV Charging Infrastructure.

Learn more about our thermal management material solutions.

Sources:

(1) https://www2.deloitte.com/us/en/insights/focus/future-of-mobility/electric-vehicle-trends-2030.html

Justin Kolbe currently serves as Henkel’s Director of Market Strategy for Power and Industrial Automation within the company’s Adhesive Technology business unit, where he is focused on setting broad strategic guidance and market insights.

In 1996, Kolbe joined The Bergquist Company (acquired by Henkel in 2014) as a Process Engineer and has since worked in various capacities including process development, applications engineering, R&D and marketing.

A chemical engineer by training, he has extensive experience in thermal management solutions and electronic materials development and processing. With an impressive professional track record and a long history of providing reliable solutions for customers in multiple markets including power conversion, automotive, industrial automation and power electronics, Kolbe is passionate about ensuring Henkel materials not only deliver on performance, but also on cost and sustainability objectives. Based in Henkel’s Chanhassen, MN facility, Kolbe holds a Bachelor’s degree in Chemical Engineering from the University of Minnesota.

Tagged with: electric vehicles

Your email address will not be published. Required fields are marked *

*

*

document.getElementById( “ak_js_1” ).setAttribute( “value”, ( new Date() ).getTime() );

Download the Elektra Awards 2022 media pack and book your sponsorship package to be part of the most prestigious awards event celebrating its 20th anniversary this year!

Get the media pack »

Have your say in choosing the most promising UK university research project reported in the last year, from Bristol or ICL to Surrey or Southampton, and robotic fingers to flexible and stretchy supercapacitors…

Cast your vote »

Get our news, blogs and comments straight to your inbox! Sign up for the Electronics Weekly newsletters: Mannerisms, Gadget Master and the Daily and Weekly roundups.

Find out more »

Read our special supplement celebrating 60 years of Electronics Weekly and looking ahead to the future of the industry.

Read the Electronics Weekly @ 60 supplement »

Read the first ever Electronics Weekly online: 7th September 1960. We’ve scanned the very first edition so you can enjoy it.

Read the very first edition »

Electronics Weekly teams up with RS Grass Roots to highlight the brightest young electronic engineers in the UK today.

Find out more »

Read our special supplement celebrating 60 years of Electronics Weekly and looking ahead to the future of the industry.

Read the Electronics Weekly @ 60 supplement »

Read the first ever Electronics Weekly online: 7th September 1960. We’ve scanned the very first edition so you can enjoy it.

Read the very first edition »

View All Events

Tune into this Xilinx interview: Responding to platform-based embedded design

Listen to the interview »

Tune into this podcast to hear from Chetan Khona (Director Industrial, Vision, Healthcare & Sciences at Xilinx) about how Xilinx and the semiconductor industry is responding to customer demands.

Listen to the interview »

By using this website you are consenting to the use of cookies. Electronics Weekly is owned by Metropolis International Group Limited, a member of the Metropolis Group; you can view our privacy and cookies policy here.

Recent Comments